Kitchen and bath product maker Kohler officially opened the doors to a new manufacturing facility in Casa Grande, Arizona, yesterday.

According to the company, based in Kohler, Wisconsin, the new facility will create 400 jobs.

The facility spans about one million square feet on some 216 acres in the Grand Canyon State, so the company has plenty of room to grow. The plant makes Sterling brand bath and shower fixtures. The factory also installed advanced manufacturing technology that can create durable baths, shower receptors, and bath and shower walls. Kohler has seen double-digit growth in the fixture segment, driven by the surging U.S. housing market.

Most Read on IEN:

- Hot Sauce Maker Halts Production Due to Chili Pepper Color

- Milwaukee Tool Work Gloves Allegedly Tied to Forced Labor

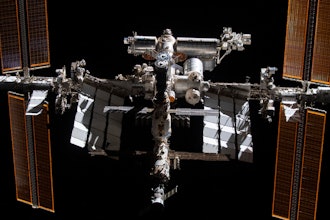

- NASA's Starliner Launch Facing 'Disaster'

- Podcast: Doomsday Plane Deal; Smelly Beermaker; Tesla Layoffs

In addition to manufacturing operations, the site also has an ancillary warehouse, a distribution center, office space, cafeterias and a showroom.

Located about an hour south of Phoenix, the new facility called for an investment of more than $300 million, which, according to the Phoenix Business Journal, is one of the largest made by Kohler in its 150-year history.

Kohler chose Casa Grande over potential sites in California, New Mexico, Texas, Nevada, Utah, and even Mexico. The company chose Casa Grande in part because of the talent pool, which includes the ability to attract workers from Tucson and Phoenix.

The new factory will also track sustainability measures to minimize greenhouse gas emissions, water use, solid waste, and energy efficiency.

In March, the U.S. Department of Energy picked Kohler to begin award negotiations for up to $51.2 million, matched by company investment, to demonstrate a commercial-scale decarbonization solution in Casa Grande.

Kohler wants to build an electric boiler and microgrid system and expects the upgrades to prevent at least 7,865 metric tons of carbon dioxide equivalent (MTCO2e) from being released annually. If successful, the effort represents a potential reduction of at least 90% of the pressing process emissions by eliminating CO2e emissions from natural gas boilers.

Furthermore, the company will install a 21 MW solar array microgrid, use long-duration energy storage (LDES) batteries with 68 MWh of storage, and install 12 MW of HVO-capable industrial backup generators. The LDES batteries, coupled with advanced microgrid controls, eliminate all possible solar curtailment scenarios (wasted solar energy) and enable the facility to run the boilers on renewable energy.

Click here to subscribe to our daily newsletter featuring breaking manufacturing industry news.